Prevent early damage caused by hydrogen

NTN company (hereinafter referred to as NTN) has developed a hydrogen embrittlement resistant bearing with three times longer service life than NTN standard bearing by combining new steel with special heat treatment technology and aiming at the early damage of bearing caused by hydrogen element.

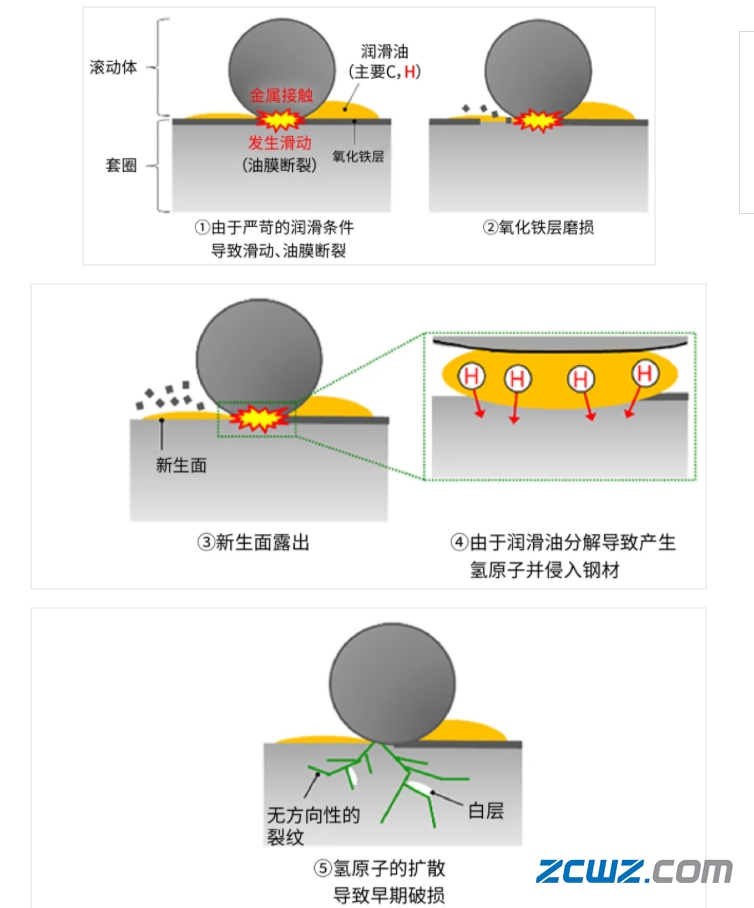

In the face of the once-in-a-century major change in the automotive field, under the background of the vigorous development of electric vehicles, the market demand for more efficient power transmission device is increasing, such as reducing the amount of lubricating oil in the device, reducing the oil viscosity and other measures to put the bearing in more stringent lubrication conditions. The bearing has never experienced severe service conditions so far, and there is early damage. The reason is due to hydrogen embrittlement, which is caused by hydrogen atoms invading into the steel. In response to this phenomenon, we must seek solutions.

NTN recently developed [hydrogen embrittlement resistant bearing] by using new steel and newly developed special heat treatment technology, which can inhibit the early damage caused by hydrogen embrittlement, is a long-life commodity. A lot of hard and fine metal compounds are dispersed on the surface of bearing raceway surface with new steel. Under the condition of thin lubrication, even the metal contact is not easy to wear, which inhibits the exposure of new metal surface * 1 which produces hydrogen atoms. In addition, even if hydrogen atoms are produced, these fine metal compounds can also inhibit the invasion speed (diffusion) of hydrogen atoms in the bearing. As a result, compared with NTN standard bearing, the service life of the developed product is increased by more than 3 times * 2. Moreover, in the special heat treatment process, the nitriding treatment is adopted to improve the nitrogen concentration on the bearing raceway surface, which inhibits the development of bearing fatigue, improves the resistance to foreign matters, and realizes the long service life under the condition of foreign matters mixed into the lubrication.

In addition, the new steel used in the heat treatment process to reduce CO2 emissions, reducing the burden on the environment.

NTN will promote this product to the whole world to further improve the reliability of automobile and industrial machinery.

*1) The very thin iron oxide layer on the metal surface is removed

*2) Under the condition of rapid acceleration and deceleration with a large amount of water in lubricating oil

characteristic

Long life

Compared with NTN standard bearing, the service life is increased by more than 3 times

Improvement of foreign body resistance

By increasing the nitrogen concentration on the raceway surface of the bearing during quenching, the service life of the bearing under the condition of foreign matters mixed in lubrication is improved

purpose

Automobile and all industrial machinery

The mechanism of hydrogen atom invading steel and leading to early damage